Introduction: Why Safety is Your Most Important Skill

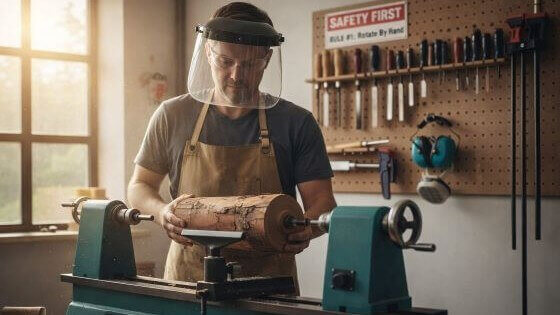

In the world of woodworking, the lathe is a unique beast. Unlike a table saw or a jointer where the tool moves, in woodturning, the workpiece itself is spinning at high speeds just inches from your face. As a veteran woodworker, I’ve seen how quickly a moment of distraction can turn into a trip to the emergency room.

Safety isn’t just about wearing goggles; it’s a mindset. Whether you just bought your cheapest wood lathe or you’re operating an industrial-sized machine, the physics of centrifugal force remain the same. This guide outlines the mandatory safety protocols that will keep you safe, productive, and—most importantly—keep all your fingers intact.

The Personal Protection Equipment (PPE) Checklist

Before you even plug in your machine, you need to “armor up.” Standard safety glasses are rarely enough when a 2-pound bowl blank decides to explode.

- Face Shield (MANDATORY): A high-impact rated face shield is non-negotiable. It protects your entire face from “catches,” flying chips, and the rare but terrifying event of a workpiece breaking apart.

- Respiratory Protection: Wood dust, especially from exotic species, is a silent killer. Always use a dust mask or a powered respirator, particularly during sanding.

- No Loose Clothing or Jewelry: This is a major cause of lathe accidents. Rolled-up sleeves, neckties, necklaces, and even rings can get caught in the spinning spindle, pulling you into the machine in a split second.

- Hair Safety: If you have long hair, tie it back securely.

The 10 Mandatory Safety Protocols

1. The “Rotate by Hand” Rule

Before flipping the power switch, always rotate the workpiece by hand for one full revolution. This ensures the wood clears the tool rest and the lathe bed. This simple 2-second habit prevents the motor from slamming the wood into a fixed metal object at 1,000 RPM.

2. Start at the Lowest Speed

Never assume the lathe is set to the correct speed. Always turn the variable speed dial to its lowest setting before starting. If you are using a manual belt-change system like the one found on the Rikon 70-105, verify the belt position first.

3. Check for Structural Defects

Inspect every wood blank for cracks, splits, or “checks.” A “pretty” piece of wood with a hidden crack is a ticking time bomb. Use a mallet to tap the wood; if it doesn’t “ring” and sounds dull or thuddy, it might have internal rot or cracks.

4. Maintain Tool Rest Clearance

Position your tool rest as close to the workpiece as possible without touching it (ideally 1/8 to 1/4 inch). Large gaps increase the leverage the wood has over your tool, which can lead to violent “catches.”

5. Stand “Out of the Line of Fire”

When first starting the lathe with a new blank, stand to the side (the “side-view” position) for at least 30 seconds. If the wood is going to fail or fly off, it usually happens in the first few seconds of rotation.

6. Secure the Tailstock and Tool Rest

Ensure the locking handles for the tailstock and tool rest are tightened firmly. A sliding tool rest during a cut is a recipe for disaster.

7. Sharp Tools are Safe Tools

Dull tools require more pressure to cut, which increases the likelihood of a catch. Learn to sharpen your essential woodturning tools frequently. A sharp tool slices the fibers; a dull tool tears them.

8. Remove the Tool Rest When Sanding

Once the turning is done and it’s time to sand, remove the tool rest entirely. It is incredibly easy for your fingers to get pinched between the spinning wood and the metal tool rest.

9. Use the Correct Speed for the Diameter

The larger the diameter, the slower the RPM should be.

- Formula Tip: A common rule of thumb is

Diameter (inches) x RPM = 6,000 to 9,000. If you’re turning a 10-inch bowl, stay under 900 RPM.

10. Never Leave a Running Lathe Unattended

If you need to step away for a phone call or a coffee, turn the machine off and wait for it to come to a complete stop.

Advanced Maintenance for Safety

Safety is also tied to how well you maintain your equipment. A neglected machine is an unpredictable one.

- Tailstock Alignment: Check your alignment regularly using our Lathe Maintenance Checklist. An misaligned tailstock creates uneven pressure and vibration.

- Clean the Bed: Keep the lathe bed free of pitch and resin so components slide smoothly and lock down securely.

Summary: Respect the Machine

Woodturning is one of the most rewarding forms of woodworking, but it demands respect. By following these mandatory safety rules, you significantly reduce the risks and allow yourself to focus on the creativity of the craft.

For more information on the official standards, I highly recommend visiting the American Association of Woodturners (AAW) Safety Page for in-depth technical safety whitepapers.

Safe turning!