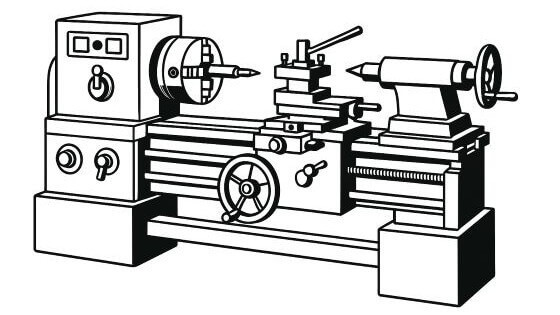

For the serious hobby machinist, model engineer, gunsmith, or small prototyping shop, the benchtop metal lathe represents a significant step up in capability from its smaller “mini” counterparts. These machines offer a compelling balance of precision, power, and capacity, all within a footprint manageable for most workshops. Unlike their larger industrial brethren, benchtop lathes provide a more accessible entry into serious metal turning, enabling the creation of accurate custom parts, threads, and intricate components.

Choosing the best benchtop metal lathe requires careful consideration of features, build quality, and intended use. This guide will explore the essential characteristics to look for, review popular categories and representative models for 2025, and help you select a machine that can become the precision workhorse of your home or small workshop.

What Defines the Best Benchtop Metal Lathe? Key Features to Consider

When evaluating benchtop metal lathes, focus on these critical aspects to ensure you get a machine that meets your precision and durability needs:

Size & Capacity (Swing, Distance Between Centers, Spindle Bore)

Benchtop metal lathes are typically larger than “mini” 7x-series lathes. Common sizes include:

- 9×19, 9×20 inches: A popular entry-point into more serious benchtop machines.

- 10×20, 10×22 inches: Offer a bit more capacity and often increased rigidity. The spindle bore (the diameter of the hole through the headstock spindle) is also crucial, as it determines the maximum diameter of stock that can be passed through the spindle.

Build Quality & Rigidity (Heavy Cast Iron is Paramount)

Precision in metal cutting demands extreme rigidity. Look for machines with substantial cast iron construction for the bed, headstock, and tailstock. This mass dampens vibration and withstands the higher cutting forces involved in machining steel and other tough materials. Precision-ground ways are essential for smooth, accurate carriage travel.

Motor Power & Type (Variable Speed Highly Recommended)

Motors typically range from 3/4 HP to 1.5 HP. Electronic Variable Speed (EVS) controlled by a DC motor is highly desirable, allowing easy RPM adjustments for different materials and operations. Some models use a geared head for speed changes, which provides excellent torque, especially at low speeds crucial for threading.

Spindle Accuracy, Bearings, & Mount

Low spindle runout is critical for precision work. Quality bearings, often tapered roller bearings, contribute significantly to spindle accuracy and longevity. Common spindle mounts might include threaded noses or more precise taper mounts like D1-3 or D1-4 on higher-end benchtop models.

Lead Screw Precision & Threading Capabilities

A precision-ground ACME lead screw is vital for accurate threading and carriage movement. The lathe should offer a comprehensive range of both imperial (inch) and metric thread pitches. Metal change gears are essential for durability in the threading geartrain.

Chuck Quality & Size

Most benchtop lathes come standard with a 3-jaw self-centering chuck (typically 5″ or 6″ diameter). The quality and accuracy of this chuck are important. A 4-jaw independent chuck is a common and valuable accessory.

Tailstock Robustness & Alignment

The tailstock needs to be robust, align accurately with the headstock spindle, and lock firmly to the bed. This is crucial for drilling operations and supporting longer workpieces with a center.

Carriage, Cross Slide & Compound Rest

These components must be well-machined, operate smoothly, and have minimal play. Adjustable gibs are necessary to take up any wear or slack over time. Larger, clearly marked dials are also beneficial.

Top Picks: Best Benchtop Metal Lathes in 2025

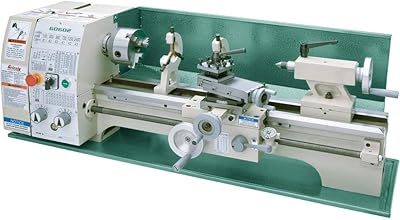

The benchtop metal lathe market features several well-regarded brands and many similar imported models offering good value. Instead of focusing on rapidly changing specific model numbers, we’ll look at feature sets common to popular categories. Common brands in this space include Grizzly, Precision Matthews, Shop Fox, Bolton Hardware, Weiss, and others.

Disclaimer: This selection is based on general market reputation for value, features, and suitability for hobbyists and small shops as of 2025. Always verify current specifications, seller reviews, and availability before purchasing.

1. The “9×20 or 10×20 Geared-Head Benchtop Lathe” – Workhorse Value

Why it’s a Top Pick: This class of lathe often provides a fantastic balance of size, rigidity, power, and features for the price. The geared head provides robust torque across a range of speeds, ideal for general machining and threading. They are often equipped with metal change gears and power cross-feed.

Typical Key Specs:

- Swing Over Bed: ~9″ or 10″

- Distance Between Centers: ~19″ or 20″

- Motor: ~3/4 HP to 1 HP, AC with geared head for speed changes.

- Spindle Bore: ~.75″ to 1″

- Threading: Comprehensive Imperial & Metric (metal change gears)

- Chuck: 3-jaw (~5″)

Pros: Good power and torque from geared head, robust construction for the price, usually includes power cross-feed, excellent threading capabilities, often a good starting point for serious hobby machining.

Cons: Speed changes require manual gear lever adjustments (not EVS), can be noisier than belt-drive EVS models. Initial setup and fine-tuning are often necessary.

2. The “10×22 Variable Speed Benchtop Lathe” – Precision & Convenience

Why it’s a Top Pick: For users prioritizing ease of use and fine speed control, a 10×22 model with Electronic Variable Speed (EVS) and often a Digital RPM Readout (DRO) is an excellent choice. These machines provide more capacity than the 9x series and the convenience of on-the-fly speed adjustments.

Typical Key Specs:

- Swing Over Bed: ~10″

- Distance Between Centers: ~22″

- Motor: ~1 HP DC with EVS

- Speed Range: Wide, typically 50-2000 or 2500 RPM (often two belt ranges)

- Spindle Bore: ~1″

- Threading: Comprehensive Imperial & Metric (metal change gears)

- Features: Digital RPM Readout, often power cross-feed.

Pros: Electronic Variable Speed offers superior convenience and optimal speed selection, larger capacity, often includes DRO, generally good precision for hobbyist work.

Cons: Typically more expensive than geared-head models of similar size; may have slightly less low-end torque than some geared-head designs unless it’s a high-quality EVS system.

3. Premium Benchtop Lathes – For Higher Precision Demands

Why it’s a Top Pick: When tighter tolerances, superior fit-and-finish, and enhanced features are paramount, brands like Precision Matthews or higher-tier Grizzly models offer machines that bridge the gap towards professional quality. They often feature better bearings, more precise lead screws, EVS, and sometimes even a factory-installed DRO.

Typical Key Specs:

- Swing Over Bed: ~10″ to 11″

- Distance Between Centers: ~22″ to 30″

- Motor: ~1 HP to 1.5 HP DC with EVS

- Spindle Mount: Often D1-3 or D1-4 taper mounts for better chuck rigidity.

- Features: High-quality EVS, DRO, excellent threading, often hardened and ground bed ways.

Pros: Higher precision and build quality, often smoother operation, robust EVS systems, excellent features for serious hobbyists or small custom work.

Cons: Significantly more expensive than standard import models.

Essential Upgrades & Accessories for Your Benchtop Metal Lathe

To maximize the utility and precision of your benchtop lathe:

- Digital Readout (DRO): Arguably the single most impactful upgrade. A DRO system provides precise digital feedback on tool position, eliminating backlash errors and making it much easier to hit exact dimensions. For a detailed understanding of how these systems work and their benefits, see our guide on What is a Digital Readout (DRO) for Lathes?

- Quick Change Tool Post (QCTP): Allows for rapid tool changes and precise, repeatable tool height setting.

- Quality Cutting Tooling: Invest in good HSS tool blanks to grind your own profiles, or sets of indexable carbide insert tools.

- Precision Measuring Instruments: Essential for metalwork. This includes dial calipers, micrometers (0-1″, 1-2″, etc.), dial test indicators, and a telescopic gauge set.

- 4-Jaw Independent Chuck: For accurately centering square, rectangular, or irregular workpieces.

- Steady Rest & Follow Rest: To support long or slender workpieces and prevent deflection or chatter.

- Collet Set & Chuck: For holding small diameter stock with high precision and concentricity.

Setting Up & Optimizing Your Benchtop Lathe

- Solid Foundation: Mount your lathe on a very sturdy, heavy workbench that is perfectly level.

- Cleaning & Lubrication: Thoroughly clean off any shipping grease. Lubricate all ways, gears, and bearings according to the manufacturer’s instructions.

- Gib Adjustment: Properly adjust the gibs on the carriage, cross-slide, and compound rest to remove any slop while ensuring smooth movement.

- Alignment Checks: Verify headstock-to-tailstock alignment.

Benchtop vs. Mini vs. Floor Lathes: Finding Your Fit

Benchtop metal lathes offer a significant step up in rigidity, power, and capacity from their smaller cousins. While this guide focuses on these robust benchtop models, if your projects are consistently very small and your budget or space is more constrained, our review of the Best Mini Metal Lathes might present more suitable options. Conversely, for industrial-scale production or very large workpieces, full-size floor-standing engine lathes provide unparalleled capability.

Considering Automation for the Future?

For users who eventually need to produce complex parts in quantity with high repeatability, the world of automated machining might beckon. To understand how computer control takes lathe work to the next level, you can explore What is a CNC Lathe Machine?

Conclusion: A Serious Investment in Precision Machining

Choosing the best benchtop metal lathe is a significant decision for any serious hobbyist or small workshop owner. These machines offer a substantial increase in capability over mini lathes, allowing for more ambitious projects, work with tougher materials, and the achievement of higher precision. Prioritize a solid cast iron build, precise spindle, accurate lead screw with comprehensive threading capabilities, and consider the convenience of Electronic Variable Speed if your budget allows.

With proper setup, quality tooling, and a commitment to learning safe machining practices, a good benchtop metal lathe will serve as a reliable and accurate workhorse for years, enabling you to create an incredible array of custom metal parts and components.