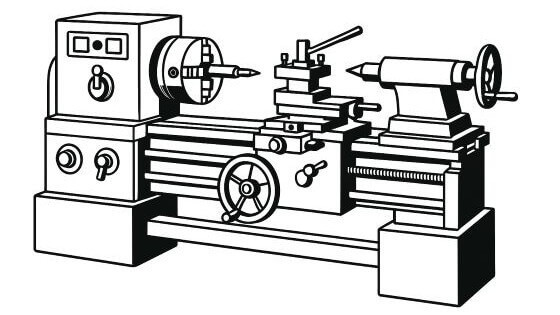

For hobbyists, model engineers, gunsmiths, or anyone needing to create small, precise metal parts, the best mini metal lathe is an invaluable tool. These compact, benchtop machines bring the capabilities of metal turning and machining into the home workshop or small business, offering a gateway to creating custom components, prototypes, and intricate designs from materials like steel, aluminum, brass, and plastics.

Choosing the best mini metal lathe can be a daunting task, with various sizes (commonly “7x” like 7×10, 7×12, 7×14 inches), features, and brands flooding the market. This comprehensive guide will cut through the confusion, highlighting what to look for in a quality mini metal lathe, reviewing popular categories and representative models for 2025, and helping you select the perfect machine to kickstart or enhance your precision machining journey.

What to Look For in the Best Mini Metal Lathe?

Before diving into specific models, understanding the key features will empower you to make an informed decision:

Size & Capacity (Swing & Distance Between Centers)

Most mini metal lathes are categorized by their “swing over bed” (maximum diameter of workpiece) and “distance between centers” (maximum length of workpiece). Common sizes include 7×10, 7×12, 7×14 inches. These numbers refer to a ~7-inch swing over bed and 10, 12, or 14 inches between centers, respectively. A larger distance between centers allows for longer workpieces.

Build Quality & Material (Cast Iron is Crucial)

For metal cutting, rigidity is paramount. Look for lathes with a solid cast iron bed, headstock, and tailstock. This provides the necessary mass and stability to minimize vibration and achieve accurate cuts.

Motor Power & Type (Variable Speed is Highly Desirable)

A DC motor with Electronic Variable Speed (EVS) is highly preferred. This allows for easy adjustment of spindle RPM to suit different materials, diameters, and operations (e.g., slower for threading, faster for finishing). Power typically ranges from 1/2 HP to 3/4 HP for mini lathes, which is adequate for small-scale metalwork.

Spindle Accuracy & Runout

The precision of the spindle and its bearings directly impacts the accuracy of your work. Low spindle runout (the amount of wobble) is critical. Quality bearings are a must.

Lead Screw & Threading Capabilities

A precision lead screw is essential for accurate carriage movement and for cutting threads. Check if the lathe can cut both imperial (inch) and metric threads, and whether it uses metal change gears (more durable) or plastic ones for the threading geartrain.

Chuck Quality & Type

Most mini lathes come with a 3-jaw self-centering chuck. Its quality and accuracy are important. Consider if a 4-jaw independent chuck (for irregular shapes) is available as an accessory.

Tailstock Alignment & Rigidity

A tailstock that aligns well with the headstock and locks rigidly is crucial for drilling accurately and supporting longer workpieces with a center.

Cross Slide & Compound Rest Precision

These components control the cutting tool’s movement. They should operate smoothly, without excessive play (backlash). Adjustable gibs for taking up slack are a good feature.

Variable Speed Control (EVS)

As mentioned, this is a game-changer for ease of use and achieving good finishes on different materials. A digital RPM readout (DRO) often accompanies EVS.

Metal vs. Plastic Gears

While some entry-level models use plastic change gears for threading to save costs, metal change gears are far more durable and preferred for longevity, especially if you plan on doing a lot of threading.

Top Picks: Best Mini Metal Lathes in 2025

The mini metal lathe market is characterized by many similar imported models often sold under various brand names (e.g., VEVOR, Grizzly, BestEquip, Erie Tools, Central Machinery). Therefore, focusing on feature sets common to popular categories is often more useful than fixating on rapidly changing model numbers.

Disclaimer: This selection is based on general market reputation, common feature sets known for value and performance in the hobbyist segment as of 2025. Always check current specifications, seller reviews, and availability before purchasing.

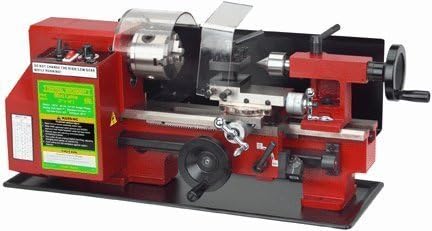

1. The Popular “7×14 Variable Speed Mini Lathe with Metal Gears” – Best Overall Value

Why it’s a Top Pick: This category represents the sweet spot for many hobbyists. The 7×14 size offers a good balance of capacity for small projects. The inclusion of Electronic Variable Speed (EVS) with a Digital RPM Readout (DRO) and durable metal change gears provides significant usability and longevity over basic models.

Typical Key Specs:

- Swing Over Bed: ~7″

- Distance Between Centers: ~14″

- Motor: ~3/4 HP DC with EVS

- Speed Range: Typically 50-2500 RPM (two ranges)

- Spindle Taper: Often MT3

- Tailstock Taper: Often MT2

- Threading: Imperial & Metric (with metal change gears)

- Chuck: 3-jaw (often 4″ or 100mm)

Pros: Excellent feature set for the price (EVS, DRO, metal gears), good capacity for hobby work, widely available from various sellers, strong community support and modification potential.

Cons: Quality control can vary between sellers/brands of these similar imports; initial setup and tuning (gib adjustment, alignment) are often required for best performance.

2. The “7×12 Variable Speed Mini Lathe” – Great Compact Option with EVS

Why it’s a Good Pick: If workshop space is very limited or your projects are consistently smaller, a 7×12 model with EVS offers most of the benefits of its 7×14 sibling in a more compact package. It’s an excellent choice for model makers or those needing precision in a smaller footprint.

Typical Key Specs:

- Swing Over Bed: ~7″

- Distance Between Centers: ~12″

- Motor: ~1/2 HP to 3/4 HP DC with EVS

- Speed Range: Typically 50-2500 RPM

- Gears: May be metal or plastic depending on the specific model/price point (metal preferred).

Pros: Compact size, Electronic Variable Speed convenience, good for very small parts and precise work, generally more affordable than 7×14 EVS models.

Cons: Limited length capacity, ensure it has metal gears if durability is a key concern for threading.

3. The Basic “7×10 or 7×12 Manual Speed Mini Lathe” – Entry-Level Budget Starter

Why it’s a Good Pick: For absolute beginners on the tightest budget wanting to simply learn the fundamentals of metal turning, these basic models offer the lowest point of entry. They are simple, straightforward, and can perform basic operations.

Typical Key Specs:

- Swing Over Bed: ~7″

- Distance Between Centers: ~10″ or 12″

- Motor: ~1/3 HP to 1/2 HP

- Speed Control: Manual belt change or basic Hi/Lo gear selector.

- Gears: Often includes plastic change gears.

Pros: Most affordable way to start metal turning, very compact.

Cons: Lacks variable speed (less convenient, harder to optimize cuts), often uses plastic change gears (less durable), lower power, may require more initial tinkering and setup for good performance.

Essential Accessories for Your Mini Metal Lathe

To truly unlock your mini metal lathe’s potential, consider these accessories:

- Quick Change Tool Post (QCTP): A massive upgrade over the standard 4-way tool post, allowing for rapid tool changes and precise height adjustment.

- Cutting Tools: High-Speed Steel (HSS) tool blanks (to grind your own custom profiles) and/or Carbide insert tooling (easier for beginners, no complex sharpening).

- Measuring Tools: Precision is key. Invest in good quality dial calipers, micrometers, and a dial test indicator with a magnetic base.

- 4-Jaw Independent Chuck: For holding square, rectangular, or irregularly shaped workpieces.

- Live Center & Drill Chuck: For the tailstock to support work and drill holes.

- Steady Rest & Follow Rest: To support long, slender workpieces and prevent chatter.

Getting the Most From Your Mini Metal Lathe

- Initial Setup & Tuning: Take the time to clean, lubricate, and properly align your new lathe. Adjusting the gibs on the carriage, cross-slide, and compound rest is crucial for smooth, precise movement.

- Learn Basic Operations: Practice facing, turning to diameter, parting, drilling, and eventually, threading.

- Safety First: Metal machining has inherent risks. Always wear safety glasses (a full face shield is better), understand chip control, avoid loose clothing, and know your machine’s emergency stop.

Upgrading for Enhanced Precision: Considering a DRO

While many mini metal lathes rely on their handwheel dials for positioning, these can be prone to inaccuracies due to backlash in the screws. A common and highly effective upgrade for drastically improving precision and ease of use is adding a Digital Readout (DRO) system. A DRO provides an accurate digital display of the cutting tool’s position, allowing you to hit exact dimensions more easily and quickly, transforming your machining experience from guesswork to certainty. This is arguably one of the best upgrades for any manual mini metal lathe.

Conclusion: Precision Machining in a Compact Package

The best mini metal lathe for you will ultimately depend on your budget, available space, and the types of projects you plan to tackle. For hobbyists and small-scale prototypers, a well-chosen machine from the popular “7x” series, particularly a 7×14 model with Electronic Variable Speed and metal gears, often provides an excellent balance of capacity, features, and value.

While these imported machines may require some initial setup and tuning to perform their best, they open up a world of precision machining possibilities without requiring the space or cost of larger industrial equipment. By understanding their capabilities, investing in good tooling and accessories (like a DRO for enhanced precision), and prioritizing safe practices, a mini metal lathe can be an incredibly rewarding addition to any workshop.