Achieving consistent precision on a manual lathe often relies on meticulously reading small graduations on handwheel dials, carefully counting turns, and frequently stopping to measure with calipers or micrometers. While skilled operators can achieve great results, this process can be slow, prone to human error, and affected by machine wear like backlash in the lead screws. Enter the Digital Readout (DRO) – a powerful electronic measuring system designed to revolutionize lathe accuracy and productivity.

But what exactly is a Digital Readout, and how does it work specifically on a lathe? If you’re looking to upgrade your machine or simply understand this common accessory, this guide is for you. We’ll explore the components of a lathe DRO system, how it provides precise position feedback, its significant benefits over traditional methods, and key considerations for adding one to your workshop.

Beyond the Dials: Why Traditional Measuring Falls Short

Before understanding DROs, it helps to recognize the limitations of relying solely on a lathe’s handwheel dials:

- Backlash: This is the “play” or slack in the lead screws and nuts. When reversing direction on a handwheel, there’s a small amount of screw rotation before the slide actually starts moving, making precise adjustments tricky.

- Dial Reading Errors: Small graduations can be hard to read accurately, leading to small but cumulative errors.

- Counting Turns: Keeping track of multiple full handwheel revolutions for larger movements is prone to miscounts.

- Wear: As lead screws wear over time, the accuracy of the dials can diminish.

A DRO system bypasses these issues entirely by measuring the actual position of the machine’s slides, not just the rotation of the handwheels.

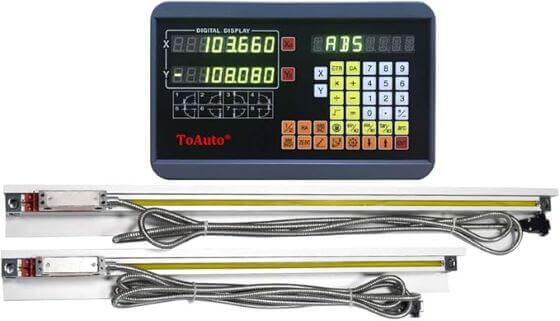

What is a Digital Readout (DRO) System? Components Explained

A typical DRO system consists of three main parts:

Scales (Linear Encoders):

These are the core measuring devices. Precision scales are mounted rigidly along the axes of travel you want to measure (typically longitudinal and cross-feed on a lathe). They contain fine markings or use magnetic principles. Common types include:

- Glass Scales: Offer very high accuracy using optical sensors reading etched glass gratings. They can be sensitive to contamination.

- Magnetic Scales: Use a magnetic strip and sensor head. Often more resistant to coolant, oil, and debris, making them durable in workshop environments, though potentially slightly less accurate than high-end glass scales.

Reading Heads (Readers/Sensors):

These compact units are mounted on the moving part of the machine slide (e.g., the carriage, the cross-slide) and travel along the corresponding scale. They read the markings or magnetic patterns on the scale to determine the precise position.

Display Unit (The “Readout”):

This is the digital console – the brain and interface of the system. It receives signals from the reading heads and displays the numerical position coordinates for each axis (e.g., X and Z). It includes buttons for essential functions like:

- Setting Zero / Datum points

- Switching between Inches and Millimeters

- Absolute (ABS) vs. Incremental (INC) modes

- Radius / Diameter display mode (crucial for lathes)

- Sometimes includes more advanced calculation functions.

How a Digital Readout (DRO) Works Specifically on a Lathe

On a lathe, a DRO system is typically configured for two axes:

- Z-Axis (Longitudinal): A scale is mounted along the lathe bed, and the reading head moves with the carriage. This tracks the carriage’s movement towards or away from the headstock, measuring lengths accurately.

- X-Axis (Cross Slide / Radial): A scale is mounted on the cross-slide, tracking its movement in and out, perpendicular to the spindle axis. Crucially, lathe DRO displays almost always feature a Diameter Mode. This means the display shows the change in the diameter of the workpiece as you move the cross-slide, rather than just the radius change. This eliminates the need for mental math (multiplying/dividing by two) when turning to specific diameters.

- (Optional) 3rd Axis: Some setups add a smaller scale to the compound slide (top slide) for precisely measuring its travel during taper turning, though 2-axis (X and Z) is the most common lathe DRO configuration.

The Powerful Benefits: Why Install a Digital Readout (DRO) on Your Lathe?

Upgrading a manual lathe with a DRO offers significant advantages:

- Dramatically Increased Accuracy & Precision: By measuring actual slide position and ignoring backlash, DROs allow for much tighter tolerances (often down to 0.0005″ or even 0.0001″ resolution depending on the scales).

- Boosted Productivity and Speed: Operators can directly machine to target dimensions shown on the display, significantly reducing the time spent stopping, measuring, adjusting, and re-measuring. Complex operations become faster.

- Reduced Errors and Scrap: Eliminates errors from misreading dials, miscounting turns, and backlash compensation, leading to fewer mistakes and less wasted material.

- Enhanced Ease of Use: Reading clear digital numbers is far easier than interpreting fine dial graduations. Functions like zeroing the display anywhere or instantly switching between inches and millimeters simplify many common tasks.

- Useful Functions: Absolute mode shows position from a fixed zero point, while incremental mode allows measuring relative movements from any point. Diameter mode on the X-axis is indispensable for lathe work.

Types of Lathe DRO Kits

When choosing a DRO, you’ll encounter variations:

- Scale Type: Glass scales generally offer the highest potential accuracy, while magnetic scales often provide better durability against workshop contaminants.

- Number of Axes: 2-axis (X, Z) is standard and sufficient for most lathe work. 3-axis adds the compound slide, useful for precise taper work but adds cost and complexity.

- Brand & Features: Kits range from basic displays showing only position to advanced units with calculators, bolt-hole pattern functions, taper calculators, tool offsets, and more.

Considerations Before Buying/Installing a Lathe DRO

- Lathe Suitability: Ensure your lathe has adequate flat, stable surfaces for mounting the scales and reading heads. The lathe should be in reasonably good mechanical condition.

- Accuracy Needs: Determine the level of precision required for your work to choose appropriate scale resolution.

- Budget: DRO kit prices vary widely based on brand, scale type, accuracy, and display features.

- Installation: DRO installation requires careful mechanical work to mount the scales parallel to the axes of travel and ensure the reading heads are properly aligned. It can be a DIY project for mechanically inclined individuals, but professional installation is also an option.

- Travel Lengths: Measure the maximum travel of your carriage (Z-axis) and cross-slide (X-axis) to order scales of the correct length.

DRO vs. CNC vs. RPM Readout: Clearing Confusion

It’s important not to confuse a DRO with related technologies:

- DRO (Digital Readout): A measuring and display system. The operator still manually turns the handwheels to move the machine slides.

- CNC (Computer Numerical Control): An automation system. A computer controls motors that move the machine slides based on a pre-written program. CNC includes position feedback but fully automates the movement.

- RPM Readout: A simple digital display showing only the rotational speed of the lathe spindle, not the position of the cutting tool.

Is a DRO Worth It for Your Lathe?

For most machinists and serious woodturners using a manual lathe, adding a DRO is considered one of the most impactful upgrades you can make. The boost in accuracy, speed, and reduction in errors often justifies the cost, especially if you perform precision work or repetitive tasks.

The value of a DRO often depends on the lathe you’re putting it on and the work you do. While a DRO can significantly upgrade even a basic machine, pairing it with a solid, reliable lathe ensures you get the most benefit from the added precision. If you’re currently choosing a machine, consider that many options reviewed in our broader guides, such as the Best Wood Lathes of 2025 or the Best Mini Metal Lathes of 2025, provide an excellent foundation for potentially adding a DRO system later on, enhancing their capabilities even further.

Conclusion: Precision Measuring for Your Lathe

In essence, a Digital Readout (DRO) system acts as a high-precision electronic ruler specifically tailored for your lathe’s movements. By replacing reliance on potentially inaccurate handwheel dials with direct measurement via scales, it empowers operators to work faster, more easily, and with significantly greater accuracy. While requiring an investment and careful installation, a lathe DRO is widely regarded as a transformative upgrade that dramatically enhances the capability and usability of almost any manual lathe, reducing frustration and improving the quality of finished work.