In the realm of manufacturing and precision engineering, the evolution from manually operated tools to automated systems has been transformative. While traditional lathes have long been the workhorses for shaping cylindrical parts, the advent of computer technology introduced a new level of precision, efficiency, and complexity: the CNC lathe machine. But what is a CNC lathe machine, and how does it differ from its manual counterpart?

This comprehensive guide will delve into the world of Computer Numerical Control (CNC) lathes. We’ll explore their fundamental definition, unravel how they work through programmed instructions, identify their key components, highlight the significant advantages they offer, and discuss their diverse applications in modern industry. Whether you’re a student, a hobbyist looking to understand advanced machining, or a professional, this article will provide a clear understanding of these sophisticated turning machines.

From Manual Skill to Programmed Precision: The Essence of CNC

To understand a CNC lathe, it’s helpful to first recall the basics of a manual lathe. A manual lathe shapes material by rotating a workpiece while a cutting tool, controlled by the operator via handwheels, is fed into it. The operator’s skill dictates the accuracy, finish, and complexity of the part.

CNC, which stands for Computer Numerical Control, takes this process and automates it. Instead of manual adjustments, a CNC lathe machine uses a computer controller to interpret a pre-written program of instructions. This program dictates every movement of the cutting tools, spindle speed, coolant flow, and other operational parameters with extremely high precision. Essentially, CNC translates a digital design into a physical, precisely machined part.

How Does a CNC Lathe Machine Work? The Core Principle

The operation of a CNC lathe follows a precise, automated workflow:

Design & Programming (CAD/CAM & G-Code/M-Code):

- Design (CAD): The process usually begins with a 2D or 3D design of the part created using Computer-Aided Design (CAD) software.

- Programming (CAM/Manual): This design is then translated into a set of instructions the CNC machine can understand. This can be done:

- Manually: By writing G-code (which defines the geometry of tool movements – e.g., linear moves, arcs) and M-code (miscellaneous functions – e.g., spindle start/stop, coolant on/off, tool changes).

- Automatically (CAM): Using Computer-Aided Manufacturing (CAM) software, which takes the CAD model and automatically generates the complex G-code toolpaths, especially for intricate shapes.

The CNC Controller: The Machine’s Brain

The generated program (G-code and M-code) is loaded into the CNC controller. This specialized computer acts as the brain of the lathe. It reads and interprets each line of code in sequence and translates these instructions into electrical signals.

Actuation: Motors & Drive Systems for Precise Movement

The electrical signals from the controller are sent to servo motors or stepper motors. These motors are connected to the machine’s slides (typically X-axis for cross-movement/diameter control and Z-axis for longitudinal movement) and sometimes the tool turret.

- Ball Screws: Instead of traditional lead screws found on many manual lathes (which can have backlash), CNC lathes almost universally use precision-ground ball screws. These convert rotary motion from the motors into highly accurate, smooth, and backlash-free linear motion for the slides. This ensures the cutting tool moves exactly as programmed.

Machining the Part:

The workpiece is clamped in the chuck or collet. The program initiates, the spindle rotates the workpiece at the programmed speed, and the cutting tools, mounted in a turret, are moved precisely by the servo/stepper motors and ball screws to perform operations like turning, facing, threading, grooving, and contouring, all according to the G-code instructions.

Key Components Specific to or Enhanced in CNC Lathes

While sharing basic lathe principles, CNC lathes have components specifically designed for automation and precision:

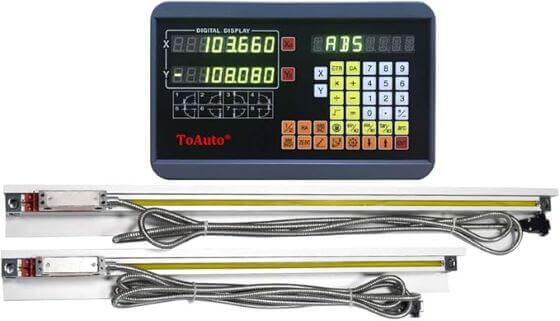

- CNC Controller & Interface: A dedicated computer with a screen and keypad/touchscreen for loading programs, editing parameters, monitoring the machining process, tool offsetting, and diagnostics.

- Servo Motors / Stepper Motors: Provide the precise, controlled power to move the machine axes and index the tool turret. Servo motors offer closed-loop feedback for higher accuracy.

- Precision Ball Screws: Ensure accurate and responsive movement of the slides with minimal friction and no backlash.

- Automatic Tool Turret / Tool Changer: A defining feature. The turret can hold multiple (e.g., 8, 12, or more) pre-set cutting tools. The CNC program can automatically index the turret to bring the required tool into cutting position, enabling complex parts with multiple operations to be machined in a single setup without manual tool changes.

- High-Precision Spindle: Designed for consistent speed and minimal runout, often with sophisticated bearings.

- Automated Chuck / Collet Closer (Optional): In production environments, chucks or collet closers can be automated for faster workpiece loading/unloading, sometimes integrated with bar feeders.

- Full Enclosure: Most CNC lathes are fully enclosed with interlocked doors for operator safety, containment of chips and coolant, and noise reduction during high-speed automated operations.

CNC Lathe vs. Manual Lathe: Key Differences Summarized

| Feature | CNC Lathe Machine | Manual Lathe Machine |

|---|---|---|

| Control | Computer Program (G-code, M-code) | Manual Handwheels & Levers |

| Precision | Extremely High, Consistent | Operator Skill & Machine Condition Dependent |

| Repeatability | Excellent (Identical parts in batches) | Variable, Operator Dependent |

| Complexity of Parts | Complex Contours & Profiles Easily Machined | Limited or Very Difficult to Achieve |

| Operator Skill | Programming, Setup, Monitoring | High Manual Dexterity, Feel for Cutting |

| Production Speed | Much Faster for Batches, Continuous Operation | Slower, Suited for One-offs or Small Runs |

| Setup Time | Can be longer for first part (programming) | Often quicker for simple one-off parts |

| Cost | Higher Initial Investment | Lower Initial Investment |

| Flexibility | High (change program for different parts) | High (operator adapts easily) |

While this comparison highlights the operational shifts, a deeper dive into manual machines can provide richer context. For example, understanding the specific setup and tooling for a woodturning lathe or the precision considerations of a manual metal engine lathe can further illuminate the revolutionary impact of CNC automation.

Primary Operations Performed on a CNC Lathe

CNC lathes perform the same fundamental operations as manual lathes but with automation and superior precision. They excel at:

- Turning: Straight, taper, and complex contour turning.

- Facing: Creating flat surfaces.

- Grooving: Machining internal or external grooves.

- Threading: Cutting various types of threads (metric, imperial, tapered, multi-start) accurately.

- Drilling & Boring: Creating and finishing holes precisely on-axis.

- Parting Off: Separating the finished part.

- Contouring: Creating complex curved surfaces and profiles.

- With Live Tooling (on Turning Centers): Milling, off-axis drilling, tapping, and other operations on the same machine.

Unmatched Advantages of Using a CNC Lathe Machine

The adoption of CNC technology in lathes brings numerous benefits:

- Superior Precision & Accuracy: Consistently achieve tight tolerances far exceeding manual capabilities.

- Exceptional Repeatability: Once programmed, a CNC lathe can produce hundreds or thousands of virtually identical parts.

- Increased Productivity: Faster cycle times, automated tool changes, and the potential for unattended operation (with bar feeders/robots) significantly boost output.

- Machining of Complex Geometries: Intricate shapes, contours, and profiles that are impractical or impossible on manual lathes become feasible.

- Reduced Operator Error & Fatigue: Automation handles the repetitive and demanding movements, leading to fewer mistakes.

- Optimized Material Usage & Tool Life: CAM software can optimize toolpaths to reduce waste and extend tool life.

- Flexibility for Varied Production: Switching between different part programs is relatively quick, making them suitable for both high-volume and small-batch custom production.

- Reduced Need for Skilled Manual Machinists (for operation): While skilled programmers and setup personnel are crucial, the actual machine operation requires less manual dexterity.

Types of CNC Lathes

CNC lathes come in various configurations:

- CNC Turning Centers: This term often implies more advanced CNC lathes equipped with features like live tooling (milling/drilling heads on the turret), sub-spindles (for back-working parts), Y-axis (for off-center machining), and bar feeders for automated production.

- Flat-Bed CNC Lathes: Retain a traditional lathe bed layout but are retrofitted or built with CNC controls.

- Slant-Bed CNC Lathes: Feature a bed that is slanted (e.g., 30, 45, or 60 degrees) towards the operator. This design offers better chip flow, easier operator access, and increased rigidity, making them popular for production.

- Vertical CNC Lathes (VTLs): The spindle is oriented vertically, and the workpiece is mounted on a horizontal rotating table. Used for machining large, heavy, and often disc-shaped parts.

Diverse Applications of CNC Lathes

CNC lathes are workhorses across numerous industries:

- Aerospace: Precision components, engine parts, fittings.

- Automotive: Engine components (crankshafts, camshafts), transmission parts, axles, custom fittings.

- Medical: Surgical instruments, implants, custom prosthetic components.

- Oil & Gas: Valves, fittings, threaded connectors, downhole tool components.

- Electronics: Housings, connectors, precision shafts.

- General Manufacturing: Any industry requiring precision turned parts in various materials.

- Prototyping & Custom Machining: Creating one-off or small-batch custom parts efficiently.

Conclusion: The Standard in Automated Precision Turning

So, what is a CNC lathe machine? It is a highly automated machine tool that uses computer numerical control to precisely guide cutting tools along a rotating workpiece, producing parts with exceptional accuracy, repeatability, and complexity. By integrating computer programming with robust mechanical systems, CNC lathes have revolutionized manufacturing, enabling the efficient production of everything from simple shafts to intricate aerospace components. They represent a significant leap from manual lathes, offering unparalleled productivity and precision that are indispensable in today’s technologically advanced industrial landscape.