So, you’ve got your eye on a wood lathe, or perhaps you’ve just brought one home. Congratulations! The lathe itself is the heart of the woodturning workshop, but it’s only the beginning. To transform raw wood into beautiful turned objects, you need the right wood lathe tools and accessories. The sheer variety can seem daunting at first – gouges, chisels, chucks, centers – what do you really need to get started, and what else can enhance your craft?

This guide is designed to navigate the world of woodturning tools and essential wood lathe accessories. We’ll cover the core cutting tools, vital work-holding devices, sharpening necessities, safety equipment, and other helpful additions, whether you’re setting up your first turning station or looking to expand your capabilities in 2025.

The Foundation: Essential Woodturning Tools (Cutting Tools)

These are the tools that actually shape the wood as it spins. They primarily fall into two categories based on material:

High-Speed Steel (HSS) vs. Carbide Tipped Tools: Understanding the Difference

High-Speed Steel (HSS): The traditional choice for turning tools.

- Pros: Can be sharpened to a very fine edge, potentially offering a superior finish; provides excellent feedback from the wood; learning to sharpen HSS is a fundamental woodturning skill. Available in a wide variety of profiles.

- Cons: Requires frequent sharpening using a grinder and jigs; has a steeper learning curve for proper tool presentation and sharpening angles.

Carbide Tipped Tools: Feature small, replaceable carbide cutters attached to a steel bar.

- Pros: No complex sharpening required – simply rotate the cutter for a fresh edge or replace it when dull; easier learning curve for basic cutting; effective on harder woods, plastics, and resins.

- Cons: Cutters can be brittle; finish might not be as fine as perfectly sharpened HSS without careful technique and sanding; replacement cutters add ongoing cost.

Essential HSS Tool Shapes (A Typical Starter Set):

If you choose HSS, a basic set often includes these fundamental profiles:

- Spindle Roughing Gouge: A large, strong gouge with a deep flute used only for quickly turning square stock into a round cylinder (spindle work). Never use on bowl grain.

- Bowl Gouge: Designed with specific flute shapes (like U or V) and often a swept-back grind (like fingernail or Ellsworth) for safely and efficiently shaping the inside and outside of bowls and curved forms.

- Spindle Gouge (or Detail Gouge): Smaller than a roughing gouge, used for creating fine details like beads and coves on spindle work.

- Parting Tool: A thin, often rectangular or diamond-shaped tool used for cutting deep grooves, forming tenons (for chuck mounting), and separating (parting off) the finished piece from waste wood.

- Skew Chisel: A flat chisel with an angled cutting edge. Extremely versatile for planing smooth cylinders, cutting beads, and precise V-cuts, but notoriously challenging to master due to its tendency to catch if presented incorrectly.

- Scrapers (Round Nose, Square Nose): Flat tools used primarily for smoothing surfaces already shaped by gouges, particularly inside bowls or on flat areas. Require careful use to avoid catches.

Common Carbide Tool Shapes:

Carbide tools often come with interchangeable cutters in basic shapes: Round (for curves/hollowing), Square (for roughing/flat areas), and Diamond/Pointed (for details/V-grooves).

Work Holding: Essential Wood Lathe Tools and Accessories

These devices securely mount your wood onto the lathe:

Drive Center (Spur Drive):

Fits into the headstock’s Morse Taper. It has points that bite into the end of spindle stock, transferring the motor’s rotation to the wood.

Live Center:

Fits into the tailstock’s Morse Taper. It has bearings allowing its point (usually a cone) to spin freely with the wood, providing support to the opposite end of spindle stock without burning.

Chucks (Scroll Chucks):

Highly versatile jawed devices that screw onto the lathe’s spindle thread. The 4-jaw self-centering scroll chuck is the most common and almost essential for bowl turning and gripping tenons on spindles. Different jaw sets can be purchased to hold various shapes and sizes.

Faceplates:

Simple metal discs with holes that screw onto the spindle thread. Wood blanks (especially for bowls) are screwed directly onto the faceplate. A very secure method for initial mounting of rough or large blanks.

Drill Chucks:

Similar to those on a drill press, these mount in the tailstock via a Morse Taper arbor and allow you to drill accurately centered holes in your workpiece (essential for pen making, lamp parts, etc.).

Sharpening Systems (Crucial for HSS Tools!)

If using HSS tools, keeping them razor-sharp is paramount for safety, efficiency, and achieving a good finish. Dull tools are dangerous.

- Bench Grinder: The most common method. A slow-speed grinder (1725 RPM) is preferred over high-speed (3450 RPM) to reduce the risk of overheating the steel. Requires specialized grinding wheels (e.g., Aluminum Oxide) and sharpening jigs (like the popular Wolverine system) to consistently achieve correct bevel angles and profiles.

- Wet Grinders: Systems like Tormek use a slow-turning wet stone, eliminating overheating risk and producing very fine edges, but are generally more expensive.

- Diamond Hones: Useful for quick touch-ups between grindings.

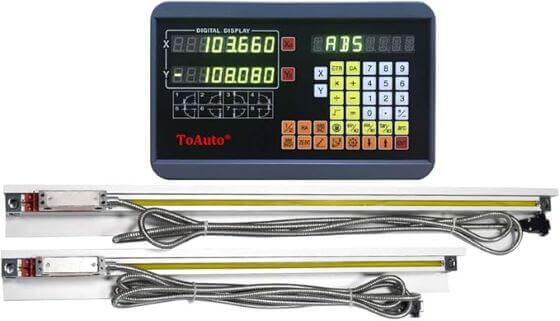

Measurement & Marking Tools

Accuracy matters in turning:

- Calipers: Essential for measuring diameters (outside calipers), internal spaces (inside calipers), and wall thickness (double-ended calipers or specialized bowl calipers). Dividers are used for marking out equal sections.

- Rulers/Tape Measures: For general length measurements.

- Pencils: For marking centers, tenon sizes, design lines.

Sanding & Finishing Supplies

- Abrasives: Sandpaper in various grits (typically 80 up to 400 or higher), often cloth-backed for durability.

- Sanding Methods: Can be done by hand (carefully!), using sanding pads held in drill chucks, or dedicated power sanding setups.

- Finishes: Various oils (like Tung, Danish), waxes (like Carnauba, Beeswax), friction polishes, lacquers, or food-safe finishes depending on the project.

Safety Gear: Absolutely Non-Negotiable!

Woodturning can be dangerous if proper precautions aren’t taken. Always prioritize safety.

- Eye/Face Protection: Full Face Shield REQUIRED. Protects your entire face from flying chips, debris, and potential tool catches. Safety glasses alone DO NOT offer sufficient protection.

- Respiratory Protection: Dust Mask or Respirator. Fine wood dust is a serious health hazard. Use at least an N95-rated disposable mask, or preferably a reusable respirator with appropriate filters. Connect dust collection if possible.

- Hearing Protection: Recommended for prolonged turning sessions.

- Appropriate Clothing: Avoid loose sleeves, remove ties and jewelry, and tie back long hair.

Other Useful Wood Lathe Tools and Accessories

As you progress, you might consider:

- Lathe Stand: If your lathe didn’t come with one or you need better height/stability.

- Dust Collection: A dedicated dust collector port or hood connected to a shop vacuum or dust collector system is highly recommended for health.

- Lighting: Good task lighting directed at the workpiece is essential.

- Knockout Bar: A metal rod used to safely remove Morse Taper accessories from the headstock and tailstock.

- Specialty Tool Rests: Different lengths or curved rests can be helpful for specific tasks.

- Steady Rest: Provides intermediate support for long, thin, or flexible spindles to prevent whipping.

Matching Tools to Your Lathe

The effectiveness and compatibility of many wood lathe accessories depend heavily on the lathe itself. Key specifications like the Morse Taper size (MT1 is smaller, MT2 is more common and versatile on midi/full-size lathes) and the spindle thread size (e.g., 1″ x 8 TPI, 1-1/4″ x 8 TPI) dictate which chucks, centers, and faceplates will fit your machine.

Ensuring your lathe has standard fittings, adequate power, and solid, vibration-dampening construction – features emphasized in many of the best wood lathes we reviewed previously – provides the widest compatibility with quality tools and accessories and allows them to perform optimally. A robust lathe forms the necessary foundation for precision work.

Conclusion: Equipping Your Woodturning Journey

While the lathe is the engine, the wood lathe tools and accessories are the components that truly drive your woodturning creativity and results. Start with the essentials: a basic set of cutting tools (choose HSS or Carbide based on your preference for sharpening vs. convenience), fundamental work holding (drive/live centers, maybe a chuck soon after), crucial sharpening supplies (if using HSS), and always, always prioritize safety gear.

As you gain experience, you can gradually expand your collection with specialized tools, different chuck jaws, and helpful accessories based on the projects you enjoy most. Equipping yourself properly not only makes woodturning more enjoyable but also safer and ultimately leads to better-finished pieces. Happy turning!